ESD Packaging Materials

Electrostatic discharge( ESD) packaging materials are made of plastic, which protects electro-sensitive products or bias that contain burnable liquids or feasts. A variety of materials are used to produce ESD packaging, and these material share a crucial point i.e. a high position of surface resistivity. The most common materials used for electrostatic discharge packaging are generally rated no further than1.0 x 103 ohm- cm of surface resistances.

Antistatic Polythene Bags

• Low density Polyethylene impregnated with antistatic property.

• Available in roll tubing, cut sheet, bags, zip lock bags.

• Surface resistivity < 10 ohms/sq.

• Prevent build-up of static charge and protect components from ESD damages

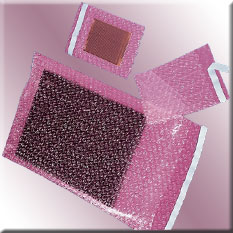

Antistatic Bubble Bags

• Low density Polyethylene impregnated with antistatic property.

• Protect components and PCB assemblies from ESD damages.

• Available in cut sheets, pouches and roll form.

• Surface resistivity < 10^12 ohms/sq.

Static Sheilding Bubble Pouch

• Combine static shielding and air bubble cushioning bag.

• Layer combination according to requirement.

• Provide EMI / RFI shielding and ESD control for PCB assemblies.

Moisture Barrier Bags

• Specially designed for dry packaging of moisture sensitive components.

• Constructed with Static dissipative outer coating, polyester

barrier layer, polyethylene and static dissipative inner coating.

• Waterproof, vapourproof and greaseproof.

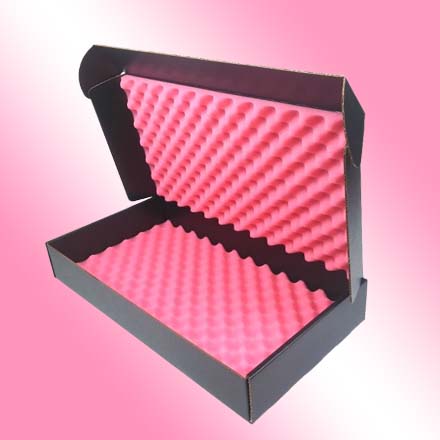

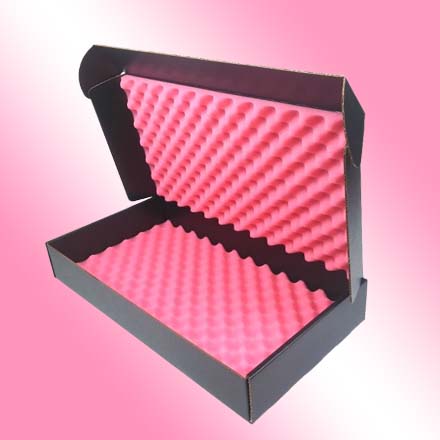

Antistatic & Conductive Foam

Antistatic Foams are available in Hard Expanded polyethylene (EPE) and Soft

Polyurethane (PU) material.

The Antistatic Foams EPE foams sheets are

available in thickness of 2mm, 5 mm and any other thickness as per

customer's requirement.

Soft Antistatic PU Foams are manufactured and

die cut as per customer's requirement.